GHT was engaged by Clear Real Estate Services, the project manager for Friendship Hospital for Animals (FHA), to deliver a state-of-the-art veterinary healthcare facility in Washington, DC. Owned by Encore Vet Group, FHA sought to relocate and expand its surgical suite, advanced imaging suite, and primary and urgent care operations from an outgrown downtown D.C. location into a 30,000 square foot space within an existing building constructed in 1982. The new facility was designed to operate 24/7 and serves as a specialty animal hospital, while the original location remains operational and continues to handle routine check-ups. GHT collaborated with key partners, including architect BDA Architecture, structural engineer Thornton Tomasetti, general contractor DAVIS Construction and developer Clear Real Estate to overcome significant challenges and deliver a healthcare-focused project tailored to the unique needs of veterinary medicine.

Navigating Patient-Grade Healthcare Design

The FHA project required GHT to integrate sophisticated healthcare systems into a space not originally designed for this use, adhering to standards like those outlined by the Facilities Guidelines Institute (FGI), which governs hospital and healthcare design. Key healthcare aspects included:

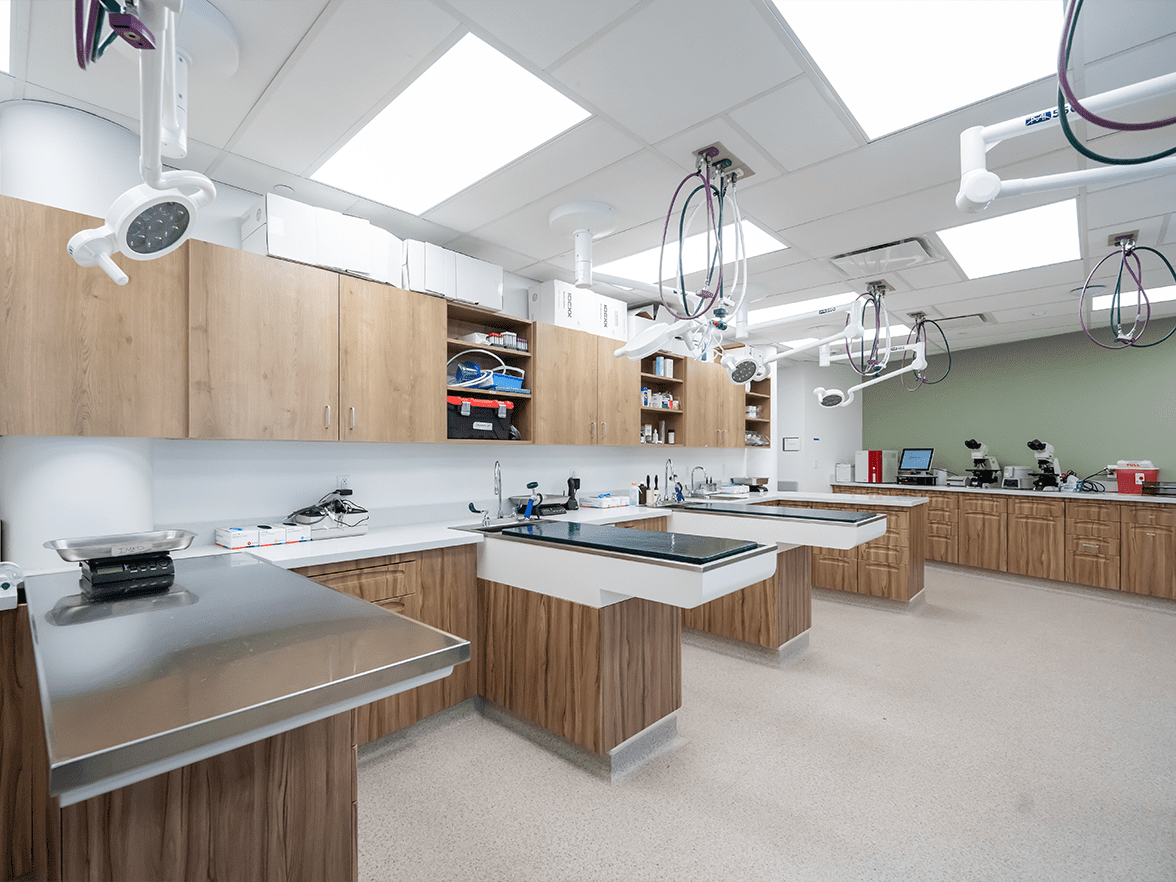

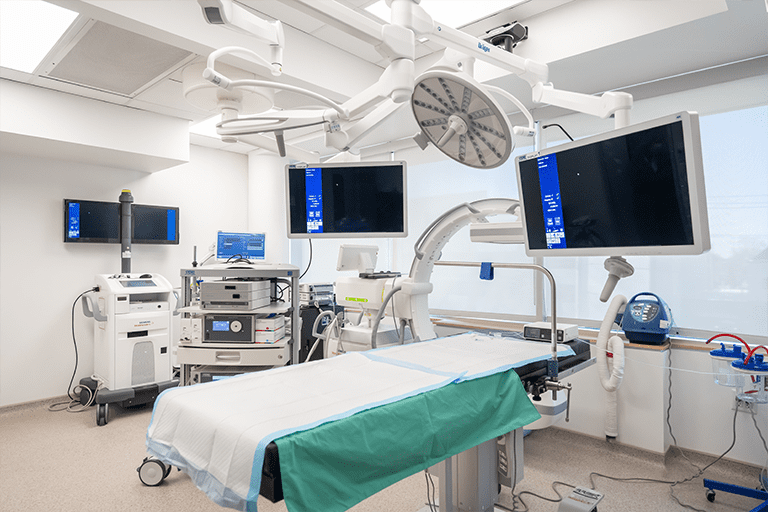

Surgical Suite Design: GHT engineered an entire-floor surgical suite equipped with patient-grade systems, including ceiling-mounted booms for monitoring heart rate, blood pressure, and medical gases, as well as surgical lights. The suite also included sterile processing autoclaves and sterile packaging areas. Compliance with FGI guidelines ensured proper air changes, pressurization, and sterility, critical for a 24/7 operating facility. Pre-close-in walkthroughs by GHT verified that all openings were sealed to maintain required pressurization–a meticulous step required in all healthcare spaces.

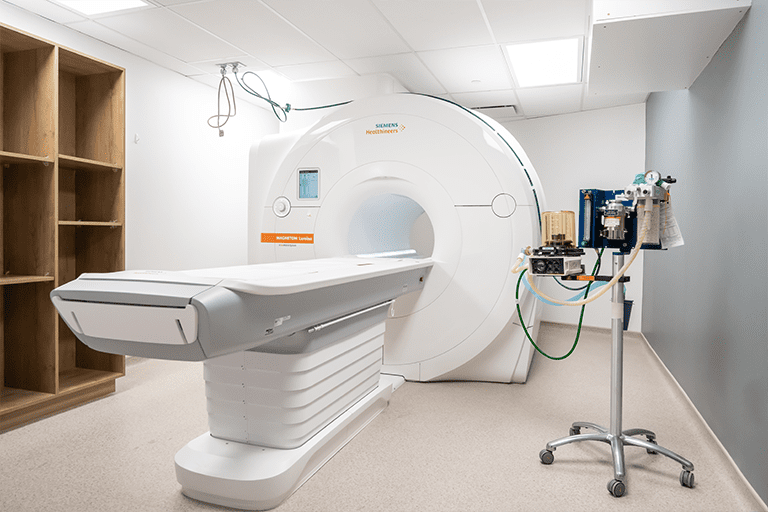

Cutting-Edge Imaging Suite: The installation of a Linear Accelerator, MRI, and CAT/CT scanning equipment demanded extensive shielding (e.g., 3-foot-thick concrete walls and lead shielding) to prevent radiation transmission into adjacent spaces. GHT coordinated with the architect and structural engineer to modify the existing brick-and-concrete structure and existing base building MEP systems, ensuring safety and compliance with healthcare radiation standards.

Oncology and Chemotherapy Facilities: A rare feature for a small veterinary facility, the oncology department included a buffer room with a fume exhaust hood for mixing chemotherapy drugs. GHT designed a system delivering 25–30 air changes per hour in a 10×10 space, using specialized diffusers to maintain hood capture velocity profile and temperature stability – demonstrating precision in meeting healthcare ventilation requirements.

Specialty MEP Systems

In addition to navigating the healthcare design standards and challenges, GHT offered unrivaled MEP design expertise on the following components:

Medical Gas and Isolation Systems: GHT designed the entire medical gas infrastructure, including a new central on-site oxygen generator system with storage tanks and oxygen bottles for back-up, Central N2 gas supply, compressed air, central medical vacuum system and vacuum exhaust were also incorporated into GHT’s design. Isolation wards, a full dental suite, and morgue freezers were also integrated, with critical systems connected to the generator for emergency power. GHT provided two master alarm panels with local area alarms and zone valves for varied areas per NFPA 99 code requirements.

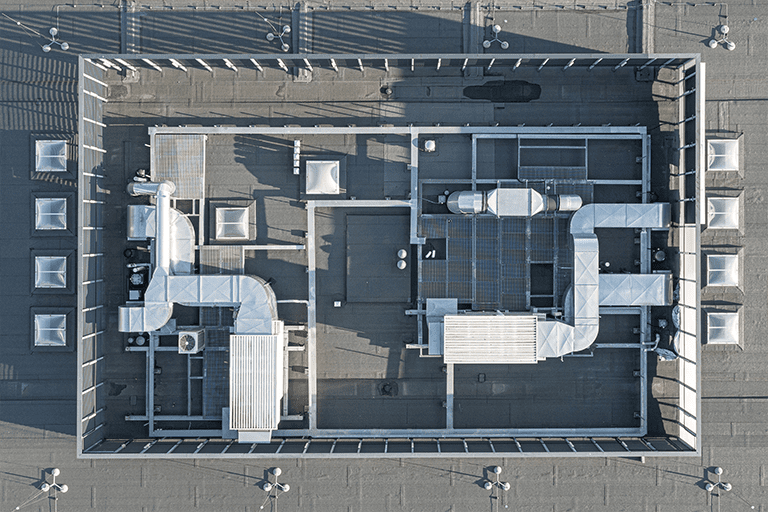

Dedicated HVAC Systems: Unlike typical shared systems, GHT designed a dedicated HVAC system for the surgical suite to ensure proper filtration and air pressure relationships between rooms, particularly in the surgery area. This approach aligned with FGI best practices, even though FHA did not pursue formal certification.

Project Challenges

The project presented significant MEP and structural complexities, compounded by the building’s age and its residential surroundings. GHT’s agile and flexible approach addressed these challenges effectively:

Challenge – Low Floor-to-Floor Height: The building’s vertically constrained structure lacked sufficient ceiling height for large ductwork required to meet hospital air change standards (e.g., surgical environments). GHT implemented fan filter units with HEPA filtration (99.99% particle removal) to circulate and mix return air with low temperature supply air, satisfying FGI air change requirements without the need for extensive ductwork. This creative solution overcame spatial limitations while ensuring a sterile environment, showcasing our adaptability to healthcare design constraints.

Navigating Service and Space Constraints

Challenge – Limited Electrical Service and Generator Placement: The building’s low-voltage electrical service (Class B) and vintage 1980’s PEPCO vaults were inadequate for healthcare systems. Generator placement in the garage posed intake/exhaust and noise issues to the building’s residents. GHT avoided costly vault replacement (saving ~$500,000) by upgrading transformers and creating a dedicated electrical room for the hospital, linked directly to a generator for ICU and life-critical systems. Facing space constraints, we placed the generator in the garage, routing exhaust to the roof and designing intake air transmission to minimize noise – a flexible solution tailored to the aging infrastructure and residential proximity. This ensured uninterrupted emergency power for surgeries and animal life-support systems.

Respecting the Community

Challenge – Noise and Disruption Near Residential Units: With apartments above and residences nearby, noise from equipment, HVAC, and construction (in a 1980s building with cracked pipes and unforeseen conditions) risked tenant complaints in a 24/7 facility. To minimize disruption, GHT coordinated with the architect to relocate residential drainage and reroute exhaust systems. We carefully selected HVAC components tied to the generator to maintain air pressure zones during outages, reducing noise impact. Our team’s prompt response to unforeseen site conditions (e.g., cracked pipes, hidden equipment) maintained project momentum, highlighting our agility and sensitivity to healthcare-adjacent residential challenges.

From projects for INOVA to Virginia Cancer Specialists, GHT’s proven approach – blending best practices with practical innovation – positions us as an ideal partner for healthcare clients seeking to navigate complex designs with confidence. For help designing your next healthcare project, reach out to Healthcare Practice Leader Brad McNiff at [email protected].